So, after not being blown away with the digital presentations, we soldiered on trying to get around to as many exhibits as possible in a two-day window. One can say thatl litho, as expected, provided more arguments for replacing older technology than Drupa 2008. Heidelberg, Komori and KBA, in particular, drew good crowds and all of them showed variants of new machinery.

Although Heidelberg did not bring a large format press to the show (they just had a static delivery unit), the launch of Anicolor in a 75-cm format was new as was the SX 102 and 75 designed presses that replace the SM Series. Heidelberg’s top line press, the new XL 106, was showcased as a perfector and as a straight press. In terms of booth appeal, Heidelberg again clearly won the show. From graphics to the indelible bass beat filling the air, Heidelberg continues to amaze in creating an outstanding environment. They didn’t have much revolutionary technology but they made the most of the SX and XL 106 coming out party.

KBA turned up with their newest size 6 machine in the 145. This press was the largest press at the show. Besides the new 105 and 75 design, KBA provided a very credible display. The continuation of KBA’s fastest make-ready press, created hype where de-clutchable plate cylinders (a manroland invention) was front and center. The 106 also can be supplied as a 20,000 iph press – the world’s fastest sheetfed. The digital Web RotaJet 76 commanded a fair amount of attention as it was coupled with Müller Martini’s finishing kit in a concept that sheeted-folded and stitched a final product. The RR Donnelly designed print engine was built around KBA’s existing web technology.

Goss (Shanghai Electric) was a cluster of various machines. The new Akiyama sheetfed, made in China, didn’t have a coater and looked like they kidnapped the Komori/Mitsubishi and Heidelberg designers, locked them in a room and squeezed a bouillabaisse of designs out of them. For that matter, Goss themselves did not seem to exhibit much sizzle with the crowds or at least when we visited. This may have been to the static nature of most of the equipment. Besides the sheetfed, Shanghai Electric made sure to include cutters and the Purlux copy of Muller's 321 and Presto stitchers too. The Goss packaging press was enclosed in its own theatre-like location.

Komori had a very business-like presentation. They not only showcased what they are developing, but also covered key sectors in a first-class fashion. The world-premiered GX 40 Carton, 41” press, was fitted with H-UV, Komori’s revolutionary drying system. Itt drew a lot of attention not only from carton printers but the general commercial user too. De-clutchable plate cylinders, new for Komori, were demonstrated on the GL 40 - closing the gap with KBA and manroland. The Lithrone A37 (37”) press saw itsdebut and clearly designed for the Indian market. It’s a budget priced press that uses the popular Indian sheet size. Finally, the Enthrone 29 was showcased as the entry level 29” press - now with a perfecting mechanism.

Manroland sheet fed and web should be applauded for just showing up. The booths were connected and very busy. However, the sheetfed demonstration we saw was surprisingly inadequate as the German presenter forgot his lines, then got himself out of sequence with the screen monitors. We watched plate de-clutching while he described in-line densitometry. Also, the press did not have “new” about it. They did, however, showcase the concept of a new console. Manroland sheetfed albeit rebuilding its presence could surprise some. The large crowds are evidence there was a great deal of interest in the company and its products. Web seemed much more of a meeting point where I’m sure customers came to get answers on what direction the business was going. We were quite surprised, even though it was generally a non machine booth, how much activity there was at manroland web. Being still considered one of the world’s leaders in litho heatset machines was evident.

In terms of technology, the printing industry is well served by what’s now available by key manufacturers. The process of driving wasted time and materials out of the process of litho printing has never been better. So, in a nutshell, what was our take on the ultimate highlight? Two distinct things:

First, we came across a company called Highcon. This Israeli firm amazed us with their Euclid die-cutting machine. Drawing on the potential that box makers want a really fast digital die cutter, the Euclid plants a polymer on a disposable foil then hardens it to make cutting and creasing rule. The process, other than mounting the foil, is automatic. Bang - out come finished cartons. Really quite impressive.

The other highlight was, again oddly, in the finishing sector. This time Müller-Martini. Besides showcasing a web finishing system at KBA’s booth (running with the RRD/KBA digital web), Müller- Martini seems to have almost reinvented themselves when it comes to listening to the market and designing machinery for shorter runs and faster make-readies. We were shown the new automated Sigma book trimmer that reads books or barcodes and can adjust itself completely from a maximum thickness and size to minimum [size] per book! Müller Martini and Highcon were inspiring.

Most of our readers will realize that we left a lot out in the review. One would need to spend every day at Drupa just to visit all exhibits. We had two days. With this in mind, apologies to the many companies that were omitted. We did try. If Drupa 2012 is going to be deemed a success, it will be in large part to orders placed before, during and immediately after the fair. But, as of this writing, it seems that confidence as well as available finance is still dragging down the industry as a whole. Clearly, very few typical Drupa announcements of machinery sales were made.

David Owen, in his well researched book – Copies in Seconds – writes: “Technology doesn’t evolve steadily and continuously. New ideas often arrive in clusters, having been generated by cumulative cultural forces whose origin and exact nature aren’t always obvious at the time or even later”. Owen’s book, about the history of Xerox, explained how ideas as well as failures in the early years [of Xerox] were a necessary part of the development of their first successful photocopier. All the companies that exhibited new offerings [this time] are hopeful they too will be the winners and their research departments will have that essential ingredient that allows survival. Everyone, especially including the competition, is watching very closely.

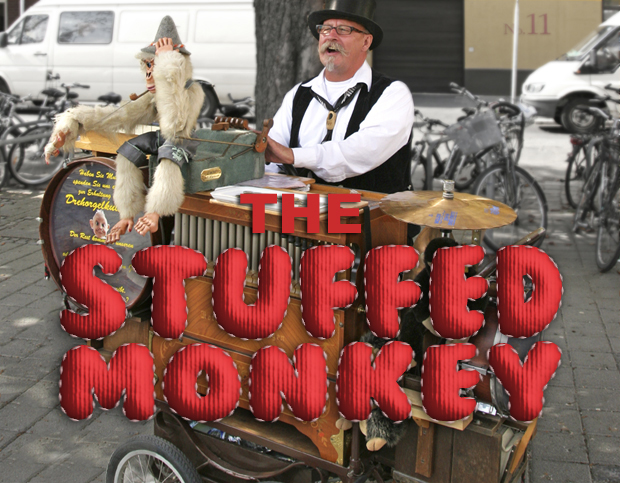

This Drupa 2012, while perhaps being somewhat overshadowed by digital machinery, nevertheless made it quite clear these new concepts will eventually displace litho as the means of printing in the under 50,000-run which is the sweet spot of commercial print. Although we began our journey full of anticipation and just as we were disappointed seeing the stuffed monkey in the Altstadt, it seemed to symbolize how pre-Drupa hype [digital] was less than fulfilled this time. But, no doubt about it we were left with positive signs of where the road is leading. Benny Landa is right and his oft-used statement is even truer today than even last year. “Everything that can be printed digital will be”.

|