|

|

| Home › Articles › Here |

|

|

||||||||||||||||

| By: Nick Howard | Date: August 2014 | Contact the Author |

Part 1 | Part 2 |

||||||||||||||||

Cont'd from Part 1 |

|||||||||||||||||

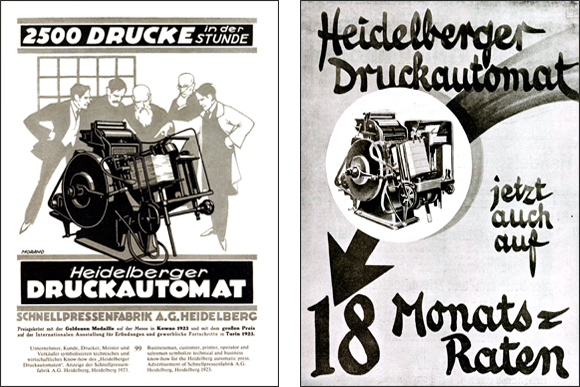

By the end of WW I, Heidelberg had such a press. Although there was management issues and very difficult times, Schnellpressenfabrik had one more important ingredient. They had a foundry. Richard Kahn, the owner at the time, also owned MAG (Maschinenfabrik Geislingen), and this allowed Schnellpressenfabrik to work completely and autonomously on their design. Heidelberg castings are unique. When I was a young kid I could see even then the quality differences between a Heidelberg and any other machine – German, English, and American. There was a special quality to a Heidelberg.

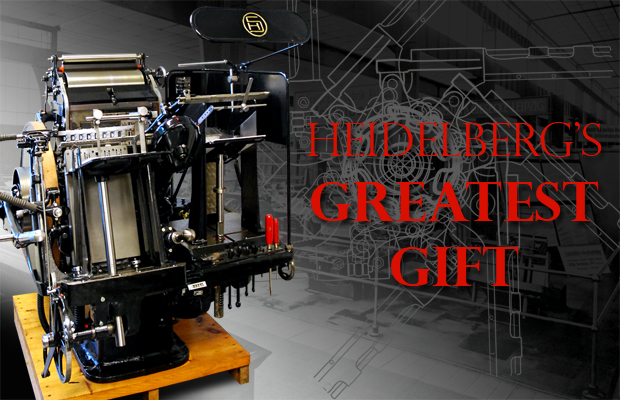

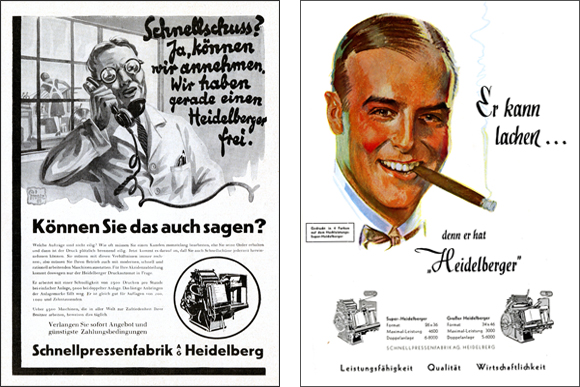

But, again world crisis had an impact, not just on Schnellpressenfabrik, but every manufacturer. The crash of 1929 was a world-wide crisis and, of course, Germany had hyper-inflation and the rise of the Nazis to deal with all through the 1930’s. Why then does this little press mean so much to so many? History shows there was competition and certainly for work such as heavy embossing one must give the Parallel press or Kluge the leg up. Why then? Heidelberg was very clever. They made their press the easiest to run. Feeding was easy, cleaning up, feeding difficult materials – even paper bags was possible. Watching a Heidelberg run is precision in motion. So exact and precise the movements. Compare that to a Gordon platen. No comparison. It is actually frightening how much better the Tiegel -as the German’s called this small platen, was. It worked in harmony with the operator. I remember my father showing me how to run the press. He became one with it. Never forced its workings and made it sing. The better the pressman the easier the work.  My memories of the Heidelberg platen trump everything else. Its sound, its strength, the fact it was almost indestructible were just some fond recollections. Heidelberg built their company on the T platen later followed by the GT (larger size) and the OHC (cylinder). What Heidelberg learned with the T platen can be seen even today. The unique suction feeder was used on the cylinder S and K models as well as the K, M, and GTO offset presses. In fact, the unique hardware, first used on the T, can be seen on the Speedmaster as late as 1994. The wonderful T platen made it possible for Heidelberg to move past all the German press makers and stay on an incredible roll right up to the flagship Speedmaster. Heidelberg owes everything to the platen. But, as we see, it took the unique genius of Heidelberg to refine and build it in their own personal style. It does not matter perhaps to those that remain in the industry, but to that whole new generation of letterpress fans, the Tiegel will make them fall in love all over again. Today, Heidelberg makes some of the finest machines in the world. Look at the XL106 or the XL162. Amazing technology.  The lithographic world is changing very fast. Even still, digital devices will eventually take over. I doubt there will ever be another printing machine that is truly loved like the Heidelberg platen. I remain in love with my Heidelberg platens. We have a 1927 and 1985 in our collection. In 1975, a Dutch artist created a musical about his Heidelberg. He wrote the music and even had the press on stage printing all around Holland. In Japan, there is a Heidelberg platen ensconced in glass outside a large printer. So loved by so many, the Tiegel transcends printing. This was Heidelberg’s gift to the printing world and reason why Heidelberg prospered and became the world’s largest press maker. |

|||||||||||||||||

Contact the Author |

|||||||||||||||||

|

|||||||||||||||