|

|

| Home › Articles › Here |

|

|

||||||||||||||||

| By: Nick Howard | Date: February 2018 | Contact the Author | |||||||||||||||||

|

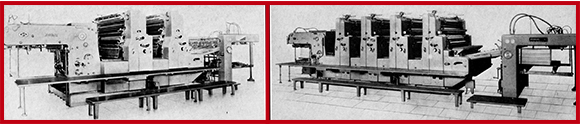

Deep inside our Howard Iron Works Museum sits an odd looking offset press. Cast in the frame the words Komori along with the once familiar Bat logo. I managed to finagle this press from the hands of an English dealer. It took years to finally pony up enough cash to get him to sell it to me. For he was a lifelong Komori man and took great pride in having this press displayed in his factory. I was told it was built in 1928, but as hard as I tried, I was never able to verify this. We had to make a couple gears for it. So after measuring we were all surprised to learn this little machine was built to imperial measurements and not metric. Why such interest? Container Corp.’s director of research said it best: “If you don’t remember the past. And are not conscious of the present, you have no future.” There are literally thousands of lessons to be learned and amazing stories to be told about our industry’s pioneers. Komori is but one excellent example. Early Tokyo Days You don’t learn much about the early days for this Tokyo-based company and, as with all Japanese engineering firms, Komori is extremely careful with its reputation. It all started on October 20, 1923, when Komori Machinery Works was formed as a private business. The print world was just awakening to the new phenomenon called offset lithography and Komori seemed to take the position – quite rare in Japanese manufacturing – to enter an immature market instead of building what everyone else was, namely letterpress machines. As near as I can research, the press we have, which is hand-fed, is a near clone of either the British Furnival or American R. Hoe. After the U.S. discovery in 1904, lithographic offset sprang to life in Japan. Prior to 1920, the Harris Automatic Press Company had sold several machines into the empire and to rave reviews. Most likely companies like Komori had taken notice. During the early 1920s, few westerners knew anything about the Japanese. Besides the arts-and-crafts business, Japan exported very little and travel was rare. In 1925, Komori’s first produced machine was a Planographic hand press (stone printing). This was a copy of America’s Fuchs & Lang lithographic press and of a very simple design. By 1928, Komori built a 32-inch hand-fed offset press – similar to the press in our museum. Early designs stemmed from duplication of English and American machines.

By 1952, big things started to happen. Komori had finally built an automatic feed offset press. This press was fitted with the American Dexter feeder and delivered to Kyodo Printing Company. By 1956, one of its very first presses, a model KW-2 with a sheet size of 26 x 39 inches was exported to Canada. It went to Montreal. Years later that press made its way to the Quebec city of Sherbrooke and by the late 1970s sold again to a printer in Oakville, Ontario. It was scrapped in the early 1980s. In 1957, Komori Currency was started and a range of Intaglio Simultan-like presses were established. Komori presses have printed Japan’s banknotes ever since much to the chagrin of KBA-Giori. The company continued to develop products, releasing a four-colour UM-4C in 1957, a five-colour in 1961 and a six-colour in 1963. That same year saw the introduction of the Kony and the Unikom models. Later the monster Kosmo, a unitized press built in the 45- and 50-inch formats, was launched. Komori marketed the Kony Super 9, then Super 10, in North America and Europe, but not the Kosmo. Opening Up Japan The 1950s opened up Japan as much as the constrained government would allow. This proved beneficial to all manufacturers as many set sail for the engineering capitals of the world. Komori did the same, for the company was already well known in Japan. The period between 1950 and 1970 was an enigmatic time for most westerners when they viewed Japanese industry. In the graphic arts, a scattering of firms made mostly facsimiles of almost everything. Even in the early 1970s, the famed English Wharfedale letterpress was still being manufactured in Japan. Hitachi Seiko also made a copy of the Heidelberg OHC cylinder press. As Japanese industrialization geared up, there was a lot going on besides cars and transistor radios. Aside from a few exports there remained no western market for Japanese printing equipment. In fact, Germany never seemed too concerned about licencing technology to fledgling engineering firms. Sumitomo – a very large corporation – was building Miller-Johannisberg presses. Yoshino, perfect binding and trimming machines from Sheridan and Martini. Even KBA had its little KRO Rapida made for a while by Ryobi. But Japan did have its close neighbours and equipment flowed all over the area from China and Korea to Indonesia and the Philippines. Komori slowly carved out a market even though by the early 70s Mitsubishi, Ryobi, Shinohara, Fuji, Sakurai and Akiyama were playing in the same sandbox. Especially in the domestic market, Mitsubishi MHI proved to be a constant irritant and major competitor. Heidelberg continues to be a major presence in Japan to this day. But few were building web presses. In 1970, Komori entered this market with the first of its blanket-to-blanket System series presses – System 25. Besides TKS, Hitachi and Toshiba, few dared competing in this segment. Goss for many years had some of its newspaper presses built here and the locals seemed to always prefer machines from the west. The 546- mm cut-off remains a favoured size in Japan and most of Asia and Komori catered to this cut-off, continuing to build this size today. Also, in 1970, someone must have seen the MAN or ColorMetal back printer. Komori added this feature to its Kosmo presses as an option. The back printer, or as Komori called it, reverse printer (RP), became a mainstay and well received addition. The RP continued with the Lithrone and won orders in carton printing for heavy board perfecting without the difficulty of building a perfector.

1981 - A Watershed Year Komori’s real breakthrough year was 1981. In that year, after exhaustive study and research, Komori came out with a press like no other, the Lithrone. This would be the moment German builders woke up and started to pay attention. What was this little company running out of three rather small manufacturing sites – Toride, Yamagata and Sekiyado – doing? And how could they possibly? I’m almost sure the former Heidelberg rebuild centre in Waldorf, Germany, was just a bit smaller than Toride. Over the next four decades, starting with the Lithrone, Komori would drive a range of innovations into the press-building world with offset innovations, factory builds, metals, and now inkjet system transports and partnerships. |

|||||||||||||||||

| Contact the Author | Cont'd to Part 2 | ||||||||||||||||

|

|||||||||||||||