|

|

| Home › Articles › Here |

|

|

||||||||||

| By: Nick Howard | Date: July 2021 | Contact the Author | |||||||||||

|

1945, with the end of the Second World War the massive print industry struggled to return to normal. All of a sudden domestic manufacturers found themselves back-logged with orders for new equipment, suddenly discovering they did not have enough skilled labor or materials. In what would soon become East Germany, remnants of a once glorious past, centering on the cities of Dresden and Leipzig, fired up their crumbling factories to take advantage of surging demand. Soon former Czechoslovakia did the same and both the East Germans and Czechs, desperate for western “hard currency”, would be looked upon as “low-cost producers”, a position they would hold for the next thirty years. Japan would follow, primarily copying western printing and bindery equipment. These three countries were the second tier and the joke was they only made Rembrandts: no two machines were ever the same in both function and quality. By the early 1960s, the small island of Formosa rose quickly to become Asia’s second powerhouse in virtually all industries; especially machine tools. Today, Taiwan remains a success story while dominating hi-tech semiconductor production, on which the world depends. In the 1960s, Taiwan replaced Japan as a cheap and low-quality producer when Japan took off matching Germany with superior technologies and products that today are considered world-class. South Korea, much closer to Japan in abilities, would benefit from proximity to Tokyo and emulate the phenomenal growth of Japan. It wouldn’t be long before Taiwan would also shrug off the “cheap and low quality” moniker and hand it to mainland China.

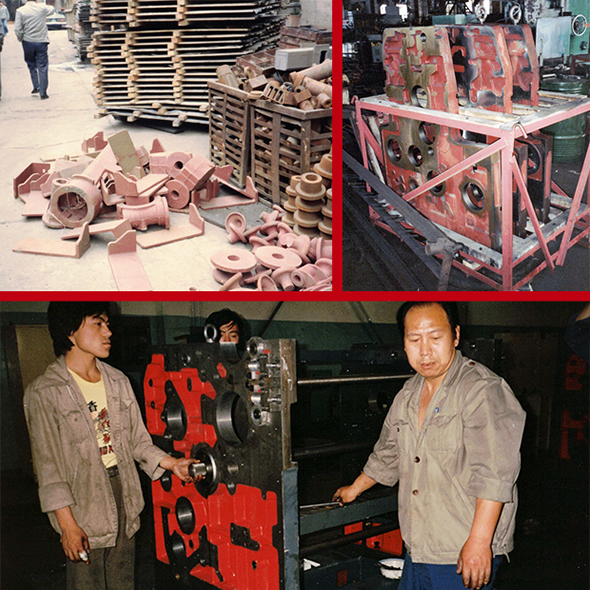

All business trade was placed under the watchful eye of government agencies and I was accompanied by a Chinese representative who liked to be called “Jack”. We got along quite well as Jack spoke excellent English while also being knowledgeable about the printing industry. What I saw during the marathon visits often shocked me. Virtually everything was a duplication of some German machine. If it was a guillotine it looked like a Polar. Presses, Heidelberg, diecutters, Bobst, Gietz or Wupa. Factories were often filthy and some still had dirt floors. Amusingly each city I visited had new world-class Hotels that exacerbated the divide between a new China and the reality of homes and factories that often had corrugated roofs and bed sheets for doors. There was a great deal of head shaking as I tried to understand how it was possible to rip off a copy of a Heidelberg so easily. At the time of China’s great awakening, there was a tremendous need for speed, and what could be easier than simply taking a used Heidelberg or Polar apart and making patterns from the parts? Intellectual property protection didn’t exist and remains a flagrant flaw today. Quality Issue However, the most pressing issue was that none of the equipment I looked at left an impression of quality engineering. To use the word “rough” was often too kind. What I did see was a rapidly growing China that had no guardrails to hinder whatever it decided to do. This was made abundantly clear whenever there were meetings with the management groups of these facilities. The CEO spoke only Chinese and often seemed less informed about the technical aspects of what his factory was producing than I did. This creation of Oligarchs repeated itself in Russia when only a few years later the Soviet Union collapsed. Men who held key political positions before the open door era were first in line to take advantage and become rich beyond any average Chinese worker's wildest dreams.

The best factory I visited was in Beijing. The Beijing Remin Machinery Co. (Beiren), had been building printing presses since 1952. The facility was making knock-offs of the Man Roland Parva Rekord, in addition to a variety of strange web presses. Years later, Beiren would manufacture inker and deliveries for Mitsubishi Diamond sheetfed and knock-offs of the Harris M300 folder. With a population (1990) of 1.2-billion people, China held all the ingredients for rapid growth. Armies of low-cost labor just begging the west to do business while offering rather unbelievably cheap prices. There were no federal watchdogs enforcing laws against pollution: the nearest ditch would suffice to dispose of liquid waste emitting from pop-up factories. Fines were unheard of and still today not nearly as strict as western countries. The Pet food and baby’s milk scandals of the 2000s are just recent missteps.

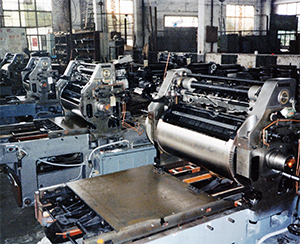

Along with our European colleagues, our company also leaped at the boundless opportunity of selling hundreds of printing and bindery machines to China; and it’s all still going on today. Positive Changes I made another trip 19 years later and what I saw the second time was dizzying. Although factories hadn’t changed much, world-class quality certainly had. Printing equipment quality had improved tremendously and unique “Made in China” designs were on full display. It’s no surprise that Bobst, Polar, and Heidelberg have built factories that churn out machinery indistinguishable from what is produced in Switzerland and Germany. Heidelberg recently announced more than 33% of all their production emanates from the Shanghai factory and more models will be produced there going forward. Many other substantial digital platforms ranging from proofers to meters-wide inkjets are growing wildly and some of you might be surprised at how much of your production equipment is produced in China.

India, with another huge population, should, on paper, be able to replicate the China story but are faced with a myriad of social struggles that the rest of the world can see but themselves. Who knows, after the incredible rise of China perhaps India might fix what's broken, and instead of their best minds leaving the country entice them to stay and build the next wave of world development? Still, the world is wary of an autocratic China. The levity of potential freedoms, which led to the crushing demise in 1989, still exists in China. Unless the Chinese Communist Party reforms there will always be friction between free democratic countries and Beijing. The China miracle continues and the rest of the world now considers both fear and envy when placing what was once referred to as Cathay, at the table. |

|||||||||||

| Contact the Author | |||||||||||

|

|||||||||||||||