|

By: Nick Howard | August 29, 2011 | Contact the Author |

| |

Komori Corporation has now launched bespoke technology they call H-UV.

The ultraviolet drying of inks is now considered a mature process. Presses equipped with UV lamps have been operating in plants for close to 50 years. The early days of lamp construction bear virtually no resemblance to current systems. Inks too were a major part of the problems (of UV). Considering limited installations, knowledgeable people who could troubleshoot and correct drying problems were hard to find.

But, a watershed moment is occurring and it’s driven by this year’s PIA InterTech™ Technology award winner – KOMORI.

|

Traditional [UV] systems have several Achilles heels. These are heat generation and high in-put wattage (=power costs). Although there have been some improvements in the industry as a whole with techniques such as LED (Light Emitting Diode) and systems that remove oxygen with inert nitrogen, both come with a cost in both currency and effectiveness.

KOMORI has, in typical Japanese thoughtfulness, said if the infra-red spectrum generated from the bulb is reduced and the ozone too, what is left is really what is essential to dry all types of substrates. The by-product of all this is lower wattage, less total lamp requirements and of course, with less IR, drastic reductions in heat.

|

|

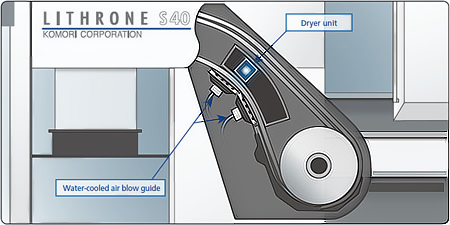

The H-UV System is an innovative UV curing system that uses a UV lamp developed with Komori know-how and high-sensitivity UV ink. With just one lamp mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance. The H-UV System is an innovative UV curing system that uses a UV lamp developed with Komori know-how and high-sensitivity UV ink. With just one lamp mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance. |

Source: www.komori.com |

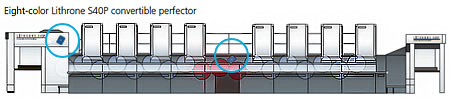

The drawing shows the placement of the H-UV lamps on an 8-color Komori LS40P with 4/4 perfector. The drawing shows the placement of the H-UV lamps on an 8-color Komori LS40P with 4/4 perfector.

|

Because of the above changes, installing this technology on long perfectors makes good sense as apparently only 2 lamps are needed to dry the sheet and impression jackets are not required. Impression jackets on any manufacturer’s machine are expensive so a potential over-time savings. The recommended ink for H-UV is widely available. If you are looking for more information on this technology, I’m afraid, there is only one company to go to and that’s KOMORI.

|

|